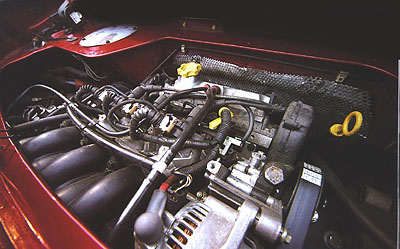

Standard VVC Inlet manifold, or more precise: the plenum chamber

M O D I F I C A T I O N S : TUNING, Engine

When going for real power gains, adding an airfilter and buying a sports exhaust system isn''t a solution anymore. Don't forget, they are providing the best power for money ratio, but the power enhacement is limited and at a certain stage too low. Starting with them isn't a waste of money, as they are becoming more restrictive while tuning the engine on a further level.

What can be done:

- Changing the inlet (manifold) and/or

throttle body (here),

optimising the amount of air and fuel.

Standard VVC Inlet manifold,

or more precise: the plenum chamber

- Fitting other camshafts:

a new set of cams will change the time that a valve opens and closes and the

lift of the cam.

- Porting and polishing

heads allows the engine to breath better and deeper.

- Fitting larger, differently shaped valves:

Improving the induction system, e.g. fitting throttle bodies, can greatly increase

the airflow into the engine, but beyond a certain level of engine tuning this

is no longer enough. As an engine is more highly tuned, and particularly as

the CR is raised, it becomes increasingly important to improve gas flow through

the head. This doesn't just mean work on the inlet and exhaust ports but also

means changing the valves.

- Fitting a turbo, supercharger

and all that kind of expensive stuff

- Installing a Power boost valve, aftermarket

ECUs and chips (ICON Race for example).

These devices will change the values comming from the sensors, providing the

ECU all the info for injection and ignition. Don't expect too much from these

on a non-Turbo-ed car. Other kind of chips are needed when some serious engine

tuning is involved as the standard ECU can not be reprogrammed. (more about

chips and magic boxes here)

- A new set of Ignition Leads (more info

here) and plugs.

- Changing the K-series engine for another

one is rather new: MG-Rover's KV6, Honda Civic Type-R, ...

I've also created a page,

that will show you some small things on how to make your engine

more secure.

The following page shows something more

about the timing of a K-series engine.

First I must add that I

don't know very much about technics --still kind of learning-- so maybe it's

wise to have a look at all kind of providers and what they are offering . .

. Going through the page you will find parts, kits, etc. from:

Mike Satur

Moto-Build

Southern

Carburettors

Powertrain

Projects

Turbo-Technics

QED Motorsport

BBR-GTi

MG XPower

Spen Vale

Garage

When MG Rover launched the

TF, they were and still are providing an 1.8 MPi with 135bhp, while the F MkI

and MkII had only 120bhp. This power gain is achieved by using a new airfilter

box, the trophy throttle body and a redesign of the exhaust system. In the beginning

we were not sure about the cams, but we must agree that the cams have been changed

slightly.

1.8 MPi

- Stage 1

Results in similar bhp figures to the VVC, more bottom end gain rather than

the top end gain

The standard 1.8i head is basically the same as the one fitted to the 1.4 K-series

engine. This results in restricted flow for the 1.8 engine. So tuning the engine

head involves gas flowing and porting with some work to the inlet valve profiles.

The standard valves and springs, (27.5mm inlet, 24mm exhaust) are retained.

This is a good mod for road use and frees the breathing up considerably. With

a suitable filter system BHP goes up to around 126 at the wheels while standard

is about 105BHP (tested by MG World). Similar gains in the torque are also achieved,

altogether a good budget option.

Supply only £450.00 (ex. VAT) Fitted with new gaskets oil etc. £850.00

(ex. VAT)

1.8 MPi

- Stage 1 Plus

An increased nhp figure

throughout the power band and with top end gains. In addition to the above (Stage

1) Mike Satur can fit a high lift inlet cam (10.87mm compared to the standard

8.8mm) with an adjustable cam gear, this allows the timing to be set accurately.

The high lift cam will give additional top end power and torque. New valve springs

are fitted to prevent coil binding. This addition costs an extra. Supply £310.00

(ex. VAT) Fitted to stage 1 head £310.00 (ex. VAT)

1.8 MPi

- Stage 2

This head is also extensively gas flowed and utilises larger valves (29.5mm

inlet, 26mm exhaust), a higher lift inlet cam and adjustable timing gears. With

filter and exhaust mods we have achieved 137BHP at the wheels on a 1.8i.

Supply only £750.00 (ex. VAT) and £1150.00 when fitted (ex.

VAT)

To optimise the power gains, Mike Satur recommends a higher lift inlet cam, adjustable vernier and new valve springs (£310.00 ex. VAT) A high lift exhaust cam and vernier can be fitted with some gain in BHP, but some lumpiness may occur (£235.00 ex. VAT)

1.8 MPi

- Stage 2 Plus

As Mike states: "... for those who love to work the engine"

This conversion gives optimum gains with new cams This involves fitting new

valves and valve seats to the same size as the VVC (31.5mm inlet, 27.5mm exhaust)

with reshaped ports and valve throats to give greater airflow, which results

in more power and torque.

Supply £950.00 (ex. VAT), Fitted £1350.00 (ex. VAT)

To optimise the power gains Mike Satur recommends a higher lift inlet cam, adjustable vernier and new valve springs (£310.00 ex. VAT). A high lift exhaust cam and vernier is recommended with more gain in BHP, some lumpiness may occur (£235.00 ex. VAT).

1.8 MPi

- Stage 3

Tthis modification is for the serious enthusiast requiring that few extra BHP.

Stage 2 plus the addition of bigger valves than the VVC (32.5mm inlet, 28.3mm

exhaust) and produces more power due to the better design of the valves and

greater air flow.

Supply £970.00 (ex. VAT), Fitted £1370.00 (ex. VAY)

To optimise the power gains Mike Satur recommends a higher lift inlet cam, adjustable vernier and new valve springs (£310.00 ex. VAT). A high lift exhaust cam and vernier is recommended with more gain in BHP, some lumpiness may occur (£235.00 ex. VAT)

1.8i performance

camshafts

"We have achieved excellent results with Piper camshafts, using profiles

that develop power throughout the rev range without having to 'pocket' the pistons

or change to solid lifters. Our 'fast road' profile is recommended for everyday

use." (Special FX, Mike Satur brochure)

VVC tuning

options

"The VVC is often ignored by tuners as being over complicated - not so

at Mike Satur! We have taken the standard VVC head and redeveloped the ports

to produce more power. Under development is a modified VVC camshaft to give

even more power." (Special FX, Mike Satur brochure)

New from

Mike Satur, the Clubman Kits

MGF 1.8i Clubman Kit (also fits the ZR and ZS cars)

"Consists of a reworked head with larger inlet valves and seats (31.5 mm

inlet up from the std 27.5mm dia) reprofiled throats ,ports, valves and combustion

chambers. The standard cams are retained but power gains up to 150BHP

can be achieved using our recommended manifold, sports exhaust , sports ca t.

and induction kit.Throttle response and torque are a considerable improvement

over the standard engine.The head is exchange or customers own unit and the

price is £675.00 plus vat A fitting service is available and this

costs £450.00 plus vat." (Mike Satur website)

MGF VVC

Clubman kit (Also fits ZR 160 cars)

"Consists of reworking valves, seats , throats and port profiles and revised

VVC cam timing, when coupled with our recommended air induction kit and exhaust

mods can produce around 175BHP with associated increase in torque and

throttle response. We recommend that we fit this kit due to the modifications

we make to the VVC mechanisms .Fitted price £895.00 plus vat"

(Mike Satur website)

Some Performance parts

Lightweight

Flywheel

"4.22 Kilos including ring gear, improve throttle and accelerator response,

ideal for tuned engines (£166.50 + VAT and delivery)." (source:

Mike Satur's website)

Uprated

Fuel Pump kit

"Standard AC Fuel pump flows approx 2 litres per minute at 3 BAR pressure.

For performance tuned vehicles under constant load this performance will drop

off and could cause fuelling problems. Our new high performance pump at 3bar

flows 4 litres per minute and will continue. (£110 + VAT and delivery)"

(source: Mike Satur's website)

1.8i MGF

Stage I

"Pipercross airfilter replacement assembly and performance silencer assembly.

This combination will yield 9BHP, removal of the catalyst yields a further 2BHP.

Total power now 128-137 BHP."

1.8i

MGF Stage II

"As Stage I, but with the inclusion of a remapped engine management ECU.

This combined with Stage I will provide an additional 16-17BHP. Total power

now 135-137 BHP."

1.8i

MGF Stage III

"As Stages I and II, but now with the addition of a pair of hydraulic type

camshafts. A different program is in the ECU, but if upgrading from Stage II

the ECU will be exchanged at no extra charge. Total power now 148-150 BHP."

1.8i MGF

Stage IV

"As Stages I, II, III, now with the addition of twin weber 45 DCOE carburettors,

filters linkages, pressure regulator and manifold. Total power now 175-180

BHP."

1.8 VVC

MGF Stage I

"Air filter replacement and performance rear silencer provides an extra

10-11BHP Total power now 155-157 BHP."

1.8 VVC

MGF Stage II

"As Stage I, but with the incusion of a reprogrammed ignition management

system a maximum of extra 20BHP is available (normally only if catalyst is removed).

Total power now 160-164 BHP."

1.8 VVC

MGF Stage III

"Currently under further development, but just under 200BHP is available

with our fully programmed fuel and ignition 4 throttle body management system.

Total power around 200 BHP."

All descriptions of

the Moto-build upgrade paths are grabbed from their website.

S o u t h e r n C a r b u r e t t o r s

"If you have already

bought a 1.8i MGF, but you're missing the extra power that a VVC could offer

you.... well read this. Southern Carburettors (SC) do many more things these

days than sell carburettors. Aside from the classic car restoration side of

the business, selling bolt-on tuning kits is the mainstay. For the MG's 'K'series

engine, the accent is on a simple bolt-on induction and exhaust kit to allow

the engine to breathe better and hence gain power and torque. And to make it

all work on best effect, a reprogrammed ECU replaces

the standard unit to enable adjustments of the fuelling and ignition mapping.

Central to the conversion is a multiple throttle body

assembly developed by SC for this application. This replaces the single throttle

butterfly fitted as standard with one butterfly for each intake tract. Its purpose

is to provide a far more accurately metered air supply for each individual cylinder

and, with a 45mm choke on each, it also allows a better flow rate. It's designed

to accept the standard fuel rail assembly and there's a carbon-fibre airbox

that matches up with the standard air filter. This conversion costs £1936

and the beauty of it is that the whole lot is a bolt-on kit that can be fitted

by the owner or by any local garage. Complementing the throttle body kit is

a performance exhaust to further enhance performance. The standard 1.8i engine

is pretty good, delivering 120bhp at around 5250rpm and with a reasonably flat

torque curve. With the SC conversion the engine delivers more power and torque

all the way through the range from 2000rpm upwards but, crucially, the power

range is extended beyond that of the standard engine. Where the stock engine's

power tails off beyond its peak at 5250rpm, the SC's better breathing allows

it to deliver strong power and torque until well beyond 6000rpm. More specifically,

it adds 20bhp, to provide a meaty 140bhp at 6000rpm, with at least 10

per cent more power than throughout the useable part of the rev range. In all

the through-the-gears tests the SC engine is quicker than the VVC." (Raby,

P., MG World Oct./Nov. 1998)

P o w e r - T r a i n - P r o j e c t s

Power-Train-Projects are offering their products on a very nice developed website. To have all the engine tuning posibilities listed on this page, I am copying data from their website to mine.

PTP are offering several upgrades for the F, some are engine related. Those upgrade paths can be divided in whole engines, performance parts and kits, containing some of the performance parts.

140

Performance 'K' Series Engine Assembly - £3995 (ex VAT)

Power 140ps

at 6500rpm

Torque 133lb/ft at 5000rpm

Power and Torque figures achieved with Janspeed performance exhaust, sports

catalyst and ITG performance induction system. Deviation form these parameters

may result in a different performance level.

The 140 performance package can be supplied in a Cylinder head kit form (see

Performance Kits (a bit further on this page (Erik))) or as a fully built, hot

tested engine configuration. The engine is SVA emissions compliant when used

with standard or PTP sports catalist converter. The engine delivers increased

power and torque with improved driveability and throttle response. It however

maintains the standard Rover Engine management system and control strategies

to maintain all service and diagnostic functionality.

The core of the package is a finely tuned cylinder head focusing not on metal

removal for maximim air flow but port chamber modifications to bestflow optimum

efficiency of the combustion process. The PTP Cast Inlet manifold with increased

plenum volume capacity is also used for optimum performance.

NOTE: Price does not include ECU and 5 AS unit

Key Features

PTP/Janspeed

modified cylinder head.

Cast

Inlet manifold with increased plenum capacity.

Standard

camshafts and valve gear maintained.

Standard

Rover MEMS ECU maintained.

All

service and diagnostic functionality maintained.

140

ps performance based upon the 1.8i engine.

Day-to-Day

driveability maintained.

SVA

emission compliant when used with the standard or PTP sports catalyst.

12

months manufacturing defect warranty.

(Data copied from the ptp-site, www.ptp-ltd.co.uk)

165 Performance

'K' Series Engine Assembly - £4999 (ex VAT)

Power 165ps

at 7000rpm

Torque 140lb/ft at 5000rpm

Power and Torque figures achieved with Janspeed performance exhaust, sports

catalyst and ITG performance induction system. Deviation from these parameters

may result in a different performance level.

The PTP 165 has been designed for upgrade of the K series 1.8i base engine in

either Cylinder head kit form (see Performance Kits) or full engine assembly.

The 165 will achieve UK SVA/MOT legislative requirements when used with the

standard or PTP sports catalyst.

The engine delivers increased top end power and significant improvement in torque

across the whole speed range. The torque curve was generated to give excellent

low speed and mid range throttle response in all gears for optimum vehicle performance

and driveability. The core of the package is a highly tuned cylinder head based

upon that used in the VHPD engine (ie large valve and ports). The head is an

evolution of the 140 again with the modifications focusing not on metal removal

for maximum air flow but port and chamber modifications to bestow optimum efficiency

of the combustion process. The PTP Cast Inlet manifold with increased plenum

volume capacity is also used for optimum performance.

The 165 incorporates new unique camshafts with high efficiency profiles and

lift characteristics, available in both mechanical and hydraulic configuration.

PTP recommend fitment of the mechanical valve gear for Track and race applications

to ensure valve control is maintained at all times. The head is manufactured

for fitment of Manual Timing belt tensioning only and hence the tensioner kit

is supplied as part of the package.

The level of head modifications and the unique camshaft arrangement has necessitated

the need for a complete remap of the engine tune parameters. PTP utilise an

EFI engine management system with unique software and tune parameter elements.

This has resulted in the improvements in performance and an engine operating

range extension to 7300rpm

Key Features

PTP

/ Janspeed modified cylinder head.

Cast

Inlet manifold with increased plenum capacity.

VHPD

based cylinder head (large valves and ports)

New

EFI ECU with the Rev Range extended to 7300rpm.

165ps

performance based upon the 1.8i engine.

Day-to-Day

driveability maintained.

SVA

emission compliant when used with the standard or PTP sports calalyst.

12

months manufacturing defect warranty.

NOTE : ECU and 5AS unit not included in price, £300.00 on cost for mechanical

valve gear option.

(Data copied from the ptp-site, www.ptp-ltd.co.uk)

190 VHPD

'K' Series Engine Assembly - £6750 (ex VAT)

PTP 190 VHPD : (190+bhp)

The 1.8i performance VHPD engine is now very well known. It is used in both

road and race applications in many of today's highly desirable sports cars.

Lotus Exige, 340R, Caterham superlight and the Westfield FW400 to name four.

A very close relationship was used by Rover in their highly successful MGF cup

single make race series.

The engine is available

in fully built form only with an option of either hot test or full run

and rate with performance curve supplied.

This seasons VHPD now incorporates the newly developed PTP multi throttle inlet

manifold and ITG Air Filter lifting the performance over 190bhp when

used in conjunction with optimised intake and exhaust systems. A Rev limit of

7800rpm, Mechanical valve gear, Ultra lightweight flywheel, 8002 Crankshaft,

forged Pistons and con rods, uprated valves and springs are also key elements

of the VHPD. SVA emission compliancy can be achieved but is vehicle application

dependent, please contact us for further details.

NOTE : Price does not include ECU and 5 AS unit

100kg

dry weight

190BHP

K-series

Race engine

Incorporating

unique Racing components

In-line

or transverse installation

Powering

two one-make race series in 1998

Supplied

to three OE Manufacturers

All performance figure's derived on test beds with optimised intake and exhausts,

figures may vary in different applications.

(Data copied from the ptp-site, www.ptp-ltd.co.uk)

Technical information here

220 Evolution

'K' Series Engine Assembly - £9800 (ex VAT)

PTP 220+ bhp Evo Race engine assembly.

The ultimate from

the PTP stable. All aspects of the 140,165HTD,and the VHPD engine development

have been evolved to create the ultimate performance from the K series engine

for the race track.

Highly modified chambers and ports, more unique camshafts, mechanical valve

gear and mechanical timing belt tensioning are key features of the EVO cylinder

head. Lighter VHPD pistons, Steel con rods, Ultra Lightweight Flywheel and a

PTP lightweight steel crankshaft combine to optimise the reciprocating components

in both strength and functionality.

The block structure is also modified and with newly designed liners to increase

rigidity and overall product reliability it copes with the speed and performance

delivered.

The induction system utilises a PTP developed multi throttle manifold designed

in which is now powering the new Lotus 340R and Exige engines.

The Evolution engine is delivered to the customer fully run in and rated ready

for immediate race use. It comes complete with a rated curve from Janspeed Motorsport

/ Race dynamometer that was also used also for all MGF cup engines

The evolution engine performance is significantly improved over that of the

current VHPD. Key features from the 140 and 165 have enable significant gains

in torque over the whole of the engine speed range to be obtained. The maximum

power is in excess of 220hp and seen at 8200rpm with the rev limit set

to 8500rpm.

SVA emission compliancy can be achieved but is vehicle application dependent,

please contact us (being PTP (Erik)) for further details.

All performance figure's derived on test beds with optimised intake and exhausts,

figure's may vary in different applications.

(Data copied from the ptp-site, www.ptp-ltd.co.uk)

Besides the full engines, they also supply performance kits

PTP

Sport 140 kit

Key features

· New (!!) and fully-assembled cylinder head

· New upper and lower modified, cast alloy inlet manifolds with increased

plenum volume capacity (subject to vehicle application)

· A sensible increase in excess of 20bhp over the standard output

· Comprehensive fitting kit and instructions

· Accurate engine dynometer test data.

· PTP body and engine appliqués.

· All products within the SPORT Performance package are NEW, no exchange

or surcharge needs to be considered.

· 12 months manufacturing defect warranty.

· Enhanced driveability

I received the following

info about this kit:

Known as the 'SPORT' engine development in PTP's unique terminology, careful

fine-tuning of components has enabled the K-Series engine in 1.8-litre form

to produce a sensible increase in excess of 20bhp over the standard output (engine

dynometer testing excluded the fitment of our 4-2-1 manifold & flexible

link pipe which may see further gains in power). According to professional,

independent testers (Autocar Magazine; EVO Magazine et al), although the power

has been clearly increased, there are also tangible improvements in mid-range

potency and top-end torque.

Much improved driveability results, with benefits felt in immediacy of throttle

response and a better aural response. The SPORT upgrade relies on the standard

engine management system and other control functions to ensure that maintenance

and diagnostic functions are uncompromised.

The principal component of the performance package is a new, fully built and

highly tuned cylinder head. All products within the SPORT Performance cylinder

head kit are NEW, no exchange or surcharge needs to be considered. The SPORT

is devised as an upgrade for the EU2 and EU3 118bhp K series 1.8i (base) engine

and will achieve UK SVA / MOT legislative requirements when used with the standard

or PTP Sports Catalyst.

The cylinder head and accompanying fitting kit is designed to be easily installed

by any professional garage. All Original Equipment parts and fitting instructions

are included.

To maximise the overall performance of the SPORT cylinder head, PTP recommends

that the ITG air box induction system and Janspeed Supersport rear silencer

are also installed.

PTP

RT-Sport 165 kit

Key features:

· A fully built brand new cylinder head assembly with large valve and

ports.

· New upper and lower modified, cast alloy inlet manifolds with increased

plenum volume capacity.

· New EFI ECU and connector lead.

· Manual camshaft belt and tensioner assembly.

· Original equipment gaskets, studs, nuts and all fittings required for

installation

· Up-rated Spark plugs.

· Cylinder head is supplied in its own purpose built box

· Accurate engine dynometer test data.

· Comprehensive fitting instructions.

· PTP body and engine appliqués.

· All products within the RT-SPORT Performance package are NEW, no exchange

or surcharge needs to be considered.

· 12 months manufacturing defect warranty.

· Day-to-day driveability maintained.

I received the following

info about this kit:

The RT-SPORT delivers outstanding power and torque improvements across the

whole engine speed range, with a potential max power output of 170ps @ 7,300rpm

(Standard 118ps) and 135lb ft of torque across a wide rev-range of 4,750-6,250rpm.

The torque curve was formulated to provide excellent low speed and mid-range

throttle response in all gears to maximise performance whilst retaining the

day-to-day driveability.

Professional testers from several publications have stated that the enhanced

driveability and greater mid-range punch have lifted the engine onto another

plane. While the RT-SPORT emits a purposeful growl during acceleration and at

high engine speeds, around town it remains highly tractable, surprisingly refined

and a genuine wolf in sheep's clothing.

The principal component of the performance package is a new, fully built and

highly tuned cylinder head (i.e. large valve and ports, 165 & 170ps power

derivatives available). Utilising PTP designed camshafts with high efficiency

profile and lift characteristics resulted in the need for a complete re-map

of the engine management system. Using an EFI control unit, with PTP developed

parameters and an increased rev-range from the standard 6,500rpm to 7,300rpm

the package delivers strong improvements.

Included with the cylinder head assembly is a modified cast alloy inlet manifold.

O.E. gaskets, studs, nuts and all fittings needed for installation to the vehicle

are supplied. The head is designed for a manual camshaft belt tensioner system

only, this allows less "whipping" of the camshaft belt at high engine

speeds (a manual tensioner and fittings are included with the RT-SPORT package).

The kit is supplied in its own purpose built box, which can be used to store

the original parts removed from the vehicle.

All products within the RT-SPORT Performance cylinder head kit are NEW, no exchange

or surcharge needs to be considered. The RT SPORT is devised as an upgrade for

the EU2 and EU3 118bhp K series 1.8i (base) engine and will achieve UK SVA /

MOT legislative requirements when used with the standard or PTP Sports Catalyst.

To maximise the overall performance of the RT-SPORT cylinder head, PTP recommends

that the ITG air box induction system, Janspeed sports catalyst converter &

Supersport rear silencer are also installed.

The parts of this

kit in more detail

The fitting instructions of this

kit

Some performance parts

Con rod

set (Steel) - £1000 (ex VAT)

For use in with most arduous Motorsport cycles for the 1.8 K-series engine.

Recommended for power outputs in excess of 200bhp

Con rod set (Forged)

- £406.84 (ex VAT)

Forged con rods

from Rover forging. Machined to PTP requirements for use with the K series engines

over 160bhp and for speeds in excess of 7300 rpm.

The Performance Con rods are shown here with the matching forged Pistons.

Crankshaft (steel Billet) - £1899 (ex VAT)

PTP designed and developed for the Evolution engine to withstand the most extreme

duty cycles. Lightweight and fully balanced, it is recommended for use with

the PTP reciprocating components.

For use with high powered high revving K Series engines (in excess of 200bhp

and over 8000rpm)

Crankshaft 8002 - £433.62 (ex VAT)

Based upon the standard 'K' Series Crankshaft but with a new casting material

specified by PTP to give 17% more strength and is machined to a new specification

defined by PTP.

fig. Crankshaft from PTP Ltd.

This crankshaft

is most commonly used on the VHPD engine with recommendation being used on engines

producing up to 200bhp

Direct to head Multi throttle inlet manifold - £650 (ex VAT)

PTP 99MY Multi Throttle Inlet Manifold

Designed and developed for the Evolution engine, however compliments the VHPD

derivative and increases engine performance over 190bhp without the need for

tune parameter adjustments.

fig. Inlet manifold for multiple throttle bodies

Shown here

as a complete manifold, the Injectors, Fuel rail, Injector harness, Potentiometer,

Stepper Motor are all carried over from original plastic inlet Manifold.

Integral throttle butterflies, reduced weight and an improved air by-pass system

combine with an ITG JC 40/75 Air Filter to give the optimum performance and

stunning looks.

Flywheel (Ultra lightweight) - £159 (ex VAT)

Designed to increase engine responsiveness and to assist in overall balance

and smoothness of the engine. The 30% lighter than standard ultra lightweight

flywheel is fitted on the Motorsport 190 VHPD and Evolution engine. This simple

but effective component can be used with a standard or heavy duty clutch and

comes complete with ring gear and balanced ready for installation.

fig. Lightweight flywheel

Linished

Camshaft Cover - £49.99 (ex VAT)

Linished Camshaft Cover When used in conjunction with the Motorsport 190 Spark

plug insert looks stunning and applies to 1.4, 1.6 and 1.8 versions of the K

Series engine

fig. Camshaft cover

Mechanical

Tappet set - £288 (ex VAT)

Manufactured to PTP specification for mechanical valve gear option and used

in the VHPD engine as standard. Improved valve control are the main advantages

of Mechanical tappet over the standard Hydraulic tappet. This type of tappet

is recommended to support extensive track use without loosing performance.

fig. Tappet set from PTP Ltd.

The

tappets are shown here with the uprated valves and springs also used on mechanical

valve gear option.

Mechanical Tappet

shim set

For use with the 1.8 K Series Mechanical valve gear

To no ones surprise they are responsible for turbo's and superchargers. They also do a kit for the MGF, that's why they got listed on this page..

fig. Turbo-Technics Supercharger

As stated on their site:

"Everyone involved in the engine industry today must be completely familiar

with the advantages of turbocharging. The simple turbocharging concept has served

us well for two decades, the advantages are far from overwhelming, and it is

by no means clear that turbocharging will be the favoured method of increasing

aspiration density in the future. The principal advantages of supercharging

compared to turbocharging include:

- More direct linkage between engine output and operator demand.

- Minimum exhaust-side thermal inertia.

- Minimum under-bonnet heat.

- Smaller size and easier packaging in many applications.

- Potentially lower cost through the avoidance of special materials.

At Turbo Technics, we took the view that package size, weight, and fuel economy

are of paramount importance in our market, and for these reasons we chose to

develop the centrifugal supercharger. The key to this design is a planetary

traction drive relying on friction between rolling elements to provide the drive

force.This approach offers the benefits of:

- Very compact packaging, with minimum length and profile.

- Low weight.

- Low noise.

- High efficiency, particularly at cruise conditions. " (as

found on www.turbotechnics.com)

The Result of their development on a Rover 1.8i K-engine, is an increase in power from 118bhp to 191bhp with a considerable broadening of the usable power band and an increase in torque of 33% at 4,000 revs/min.

The compression ratio will be reduced by fitting new strengthened lightweight pistons and shortened forged connecting rods. These items were designed by theirself. The supercharger will run up to 110.000rpm and is driven by a poly-V belt from the crankshaft. The weight of the charger is minimized to 4.8kgs. The complete exhaust system can be remained, but an upgarde to a performance system can be done for an additional cost. At the side of the intake, a new aluminium inlet manifold wil be fitted. The injection system is kept as standard except two extra injectors. Off course the system needs a new ECU. No other changes are needed.

fig. Cast Aluminium inlet

manifold

Figures

|

standard

1.8i

|

supercharged

MPi

|

supercharged

VVC

|

|

| Maximum power |

118bhp

@ 5500rpm

|

190bhp

@ 6500rpm

|

215bhp

@ 6500rpm

|

| Maximum torque |

121lb/ft

@ 4500rpm

|

170lb/ft

@ 5000rpm

|

185lb/ft

@ 6000rpm

|

| 0-60mph |

8.5s

|

6.3s

|

5.5s

|

| 30-50mph (4th gear) |

6.6s

|

4.9s

|

1.6s

|

| 50-70mph (4th gear) |

7.0s

|

5.2s

|

4.8s

|

In the table above, the power value achieved for the VVC was when a sportexhaust system was fitted.

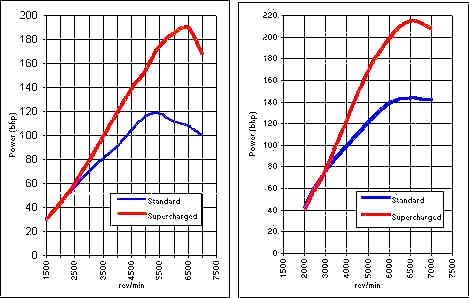

fig. power output graph

for the MPi (left) and the VVC (right) standard (Blue) and Supercharged (Red)

(source: Turbo-Technics)

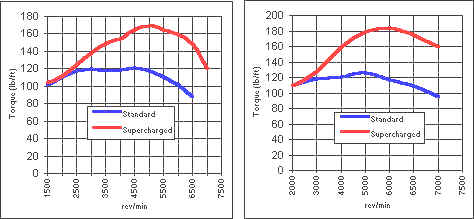

fiq. torque graph for

the MPi (left) and VVC (right) standard (Blue) and Supercharged (Red)

(source: Turbo-Technics)

The upgrade will ask you £4950.00 + VAT which includes fitting and a 12 month mechanical warranty. If you're opting for the additional exhaust, you can add another £230.00 + VAT to the bill.

For those intested they even do supercharging a Lotus Exige or 340R up to 260bhp....

Well known, especially in the Vauxhall/Opel scenes, QED Motor Sport can offer a wide scale of serious tuning options. It looks like customisation is one of their keywords. Following text is found at their website.

Workshop

Services

Standard Head

Rebuilds

There are three options commonly requested for the standard cylinder head with

applications ranging from fast road to club level competition.

- Fast Road Head Rebuild: The head is stripped,

chemically cleaned and inspected. Valve guides are replaced with our Colsibro

bronze version and stage one cams are fitted.

- Trackday Head Rebuild Package: The head is stripped

cleaned and inspected, with Colsibro bronze guides and stage one cams fitted

as above. In addition the inlet and exhaust ports are lightly worked to improve

gas flow and matched to direct to head throttle bodies, which are supplied and

fitted.

- Clubman Head Rebuild Package: This is about as

far as a standard head can sensibly be developed. Strip, clean, inspection and

fitting Colsibro guides is as above but our stage four cams are fitted (Q425MK

inlet and Q395MK exhaust). Inserts are fitted to convert the standard cam followers

into solid followers, and uprated springs are also included. Oversized inlet

and exhaust seats are fitted and formed to accommodate our oversized valves.

Porting work is more extensive, and as above direct to head throttle bodies

are fitted with ports being matched. Because the cams fitted give higher lift

than standard this head cannot be safely assembled to a standard bottom end.

VHPD/VVC Head Rebuilds

Both of these heads already have larger valves and ports but for motorsport

applications we also offer two further service levels.

- Clubman Head Rebuild Package: The head is stripped

cleaned and inspected with Colsibro bronze guides fitted and our Q425MK/Q395MK

cams. Inserts are fitted to convert the standard cam followers into solid followers,

and uprated springs are also included. The standard valves are reused. Porting

work improves gas flow and matches to direct to head throttle bodies. Because

the cams fitted give higher lift than standard this head cannot be safely assembled

to a standard bottom end.

- Full Race Head Rebuild Package: Our ultimate

race head. The head is stripped, cleaned and inspected before Colsibro guides

are fitted. Our most aggressive cams are fitted, along with solid lifter inserts,

and race springs, platforms, and retainers. Our own VVC/VHPD sized valves are

also fitted. Ports are carefully worked to the highest level and matched to

a set of direct to head throttle bodies. Because the cams fitted give higher

lift than standard this head cannot be safely assembled to a standard bottom

end.

Short Engine Rebuilds

As well as head modifications we can also supply, for the more developed engine,

rebuild services for the bottom end of the engine.

- Basic Bottom End Rebuild: The block is stripped,

checked, and chemically cleaned. Reassembly includes fitting new heavy-duty

end bearings and our banded cylinder liners to improve bottom end strength.

Also included is a full balance.

- Performance Bottom End: The block is stripped,

checked, and chemically cleaned. As with the basic rebuild, heavy-duty end bearings

are fitted as well as our banded cylinder liners. The standard rods are re-used

but honed for standard sized, forged pistons. Although the rods are re-used,

the rod bolts are replaced. Also included is a full balance.These pistons accommodate

higher lift cams and so this is the basic level of short engine rebuild required

for the Clubman head or above.

- All Steel Bottom End: The block is stripped,

checked and cleaned, and then rebuilt with all steel internals. Heavy-duty end

bearing and banded cylinder liners are fitted as above but to further strengthen

the bottom end Carillo type steel con rods are fitted, and a steel crank. Forged

pistons are fitted allowing the use of high lift cams. A lightweight steel flywheel

is fitted using heavy-duty flywheel bolts, and the engine is fully balanced.

Complete Engines

Of course with combinations of the options available above we also offer complete

engines, sold on an outright basis .

- Trackday Engine: A base unit from our stock is

stripped and rebuilt to include modifications suitable for fast road/light motorsport

applications. The block is stripped and rebuilt with heavy-duty end bearings

fitted and the complete assembly is balanced to further improve bottom end durability.

A standard cylinder head is rebuilt to include our Q375HK cams and although

standard sized valves are reused they run in Colsibro bronze guides. For induction

the head is assembled with direct to head throttle bodies. Ignition is with

the standard coil but managed by a programmable ECU which is supplied with it's

own engine bay wiring loom.The completed engine is then run in, mapped and power

tested on our dyno. An even more durable variation of this engine can be supplied

for more aggressive track use including banded liners for extra bottom end strength

and optionally a dry sump and/or race clutch and flywheel.

- Basic Club MotorSport Engine: A base unit is rebuilt to include modifications that make it more suited for club level motorsport applications. The block is stripped and our banded liners are fitted along with forged pistons, and heavy-duty end bearings for extra strength. Although standard rods are reused the con rod bolts are replaced for greater strength, allowing safe use of a higher rev limit. A standard cylinder head is rebuilt to include our Q425MK and Q395MK profile cams, which includes fitting uprated valve springs and converting to solid cam followers. The head is also fitted with oversized valves, running in Colsibro bronze guides, and considerable porting work is carried out to improve gas flow. Direct to head throttle bodies are used for induction and porting work includes matching the head and bodies. The throttle bodies are fitted in our most compact arrangement using pico injectors and carbon fibre trumpets. Ignition is distributorless with a coil, ECU, and wiring loom included.The completed engine is then run in, mapped and power tested on our dyno. Variations of this engine are also supplied with a dry sump and/or race clutch and lightened flywheel for more dedicated track use.

Some

Performance Parts

Camshafts

Stage one (hydraulic): Using a Q375HK inlet cam

with a matching exhaust cam this first stage cam combination is ideal for fast

road or occasional track use. These cams are easily fitted without extensive

engine modifications. When fitted to an engine with throttle body induction

system these cams give approx. 150bhp before 7000 rpm. In a fully race prepared

engine this cam can achieve it’s full potential, delivering over 175bhp.

Stage two (hydraulic): Using a Q425HK inlet cam

with a matching exhaust cam this second stage cam combination is for more dedicated

motorsport use. Although this is a hydraulic profile the 0.425” lift requires

the uprated VHPD type valve springs. To fit at optimum timing these cams also

require pistons with deeper valve pockets. Using a standard cylinder head, 160bhp

is achieved and in a fully race prepared engine peak power should be approximately

170-180bhp.

Stage three (mechanical): Using a Q395MK inlet

cam with a matching exhaust cam this is the first of our mechanical combinations

and is about as far as aggressive a profile as can be fitted for road use. These

are a mechanical profile and require solid cam followers as well as pistons

with deeper valve pockets and uprated valve springs. With some porting work

to the cylinder head, and a throttle body induction system these cams give a

road useable 170bhp and in a fully race prepared engine can deliver up to 190bhp.

Stage four (mechanical): Using a Q425MK inlet cam

with a Q395MK exhaust cam this mechanical cam combination sees considerable

torque gains at mid range rpm making this cam combination very useful for rally

style applications. As a mechanical profile these cams again need solid cam

followers, pistons with deeper valve pockets and uprated valve springs. With

a suitable cylinder head, throttle bodies, and an appropriate exhaust system

these cams give over 200bhp.

Stage five (mechanical): Using a Q455MK inlet cam

with a Q425MK exhaust cam this combination is our current racing specification.

Suitable for use only in fully race prepared engines where this cam easily achieves

210bhp and in excess of 160 ftlb of peak torque. Our development engine when

fitted with these cams has produced 227bhp.

VVC conversion cams: The VVC in its standard form

has three cams, with the two inlet cams geared together. Competition profiles

for this unusual arrangement are not yet available. Instead we offer a traditional

one-piece cam as a direct replacement. Our VVC replacement cams are available

as any of the motorsport profiles mentioned above. In this way the VVC head

is no longer using variable valve control and customers are free to exploit

the larger valve and port sizes of the VVC head casting.

Valves

The

standard K series cylinder head:

The K series engine was first developed with a 1400cc capacity and very few

changes have been made to the cylinder head since then. Since the 1400cc engine

has 27.7 and 24.0mm valves maths suggests that an 1800cc engine should have

31.4 and 27.2mm valves. Unfortunately as standard there isn’t enough room.

Our larger than standard (29mm inlet, 26.4mm exhaust) valves are the largest

that can usefully be fitted on standard seats in front of a standard shaped

port. The QED inlet valves also have the further benefit of a wasted stem. This

reduces the diameter of the valve stem where it would normally interfere with

the gas flow and incidentally makes the valve slightly lighter.

The VVC/VHPD K series cylinder head: There are

obviously differences between these two cylinder heads but for the purposes

of discussing valve sizes they are the same. In both cases Rover presumably

realised that for a high performance engine they would need a different head

casting and so the heads for these engines have larger port sizes and come with

larger valves as standard. Since the standard VVC sized valve is already big

enough* our valves are no bigger, just a different design. As with our 29mm

valves the last portion of the inlet valve stem has a reduced diameter to improve

gas flow, but since these valves are larger, and with consideration of the stresses

on the valve train at high rpm, we have also worked to reduce the valve weight.

In the case of the inlet valves, for example, the QED valve is almost 10% lighter

than the OE item.

Pistons

Forged Forged Pistons: Our forged pistons are available

for 80mm bore size (standard 1600/1800cc bore size) and all give deeper valve

pockets than standard pistons, allowing the safe use of cams with higher lift.For

use in more developed engines we can also supply forged pistons which will typically

raise the compression ratio to 12:01. We can also supply low compression pistons

suitable for turbo/supercharged applications.

Liners

Banded Liners: In racing applications where the

engine is under more extreme stresses both in terms of load and temperature

the standard cylinder liners have been observed to fail. To strengthen the liners

and overcome this limitation we have developed our reinforced, or banded, liners.

Throttle Bodies

Tapered single bodies: The original option for

the K-series was a group of four single 45mm bodies that fit to a tapered inlet

manifold. These offer unrestricted high rpm breathing as well as maximising

mid range torque. The kit includes four bodies, inlet manifold, fuel rail and

fitments.

Direct to head bodies: The ultimate in throttle

body evolution, these bodies, as their name suggests, are designed to fit directly

to the cylinder head, disposing of the need for an inlet manifold. Dyno development

shows 42mm parallel bodies offer equivalent performance to the tapered type

bodies. However fitment is simpler, and overall weight, as well as required

space is reduced. In the least space consuming arrangement, with more compact

injectors, overall length from cylinder head face to the ends of the trumpets

is less than 7 inches.

>> More info on the page about Throttle

Bodies. <<

Engine Management System

DTA Competition engine management systems: Our

involvement with DTA management systems goes back many years and when building

a motorsport engine we wouldn’t think of using any other system. The DTA ECU

represents the state of the art in engine management systems. Full 3d mapping

of both fuel and ignition, two stage rev limiter, shift light output, fuel pump

control, transient fuel compensation (acceleration boost), closed loop fuel

mapping, and a three minute data log are amongst (but not all of) the features

available.Despite the wide capabilities of the DTA ECU the control software

is straightforward and simple to use. All of the settings are explained in the

comprehensive manual supplied with the software. For motorsport engines (and

especially for engines that will develop with each racing season as part of

an ongoing project) the DTA system is without doubt the management system of

choice. The DTA systems are capable of using a wide range of sensors including

the majority of those fitted to the K series engines as standard and these systems

are provided with an engine bay wiring loom.

>> More info on the page about chips and

management systems. <<

Lubrication

Steel oil pump inner gear: The standard gears,

which are mass-produced in a sintered material, have been seen to fatigue and

eventually break up when subjected to the greater speed and vibration encountered

in a race engine. Our gears, which are formed by spark erosion from heat-treated

carbon steel, are a sensible precaution even for a lightly modified K series

engine if it will be used aggressively. For a race engine they are an essential.

Dry Sump System: The K series engine is found in

a wide range of vehicles and so our dry sump system has been developed to be

adaptable for almost any installation. We supply the system as a kit, including

our . . .

. . . three stage pump:

- Compact design fits close to the

engine.

- Twin scavenge stages - creates sump

vacuum very effectively

- Single pressure stage - a race worthy

replacement for the standard pump

- Multiple choice of port position

- enabling use in a wide range of installations

- Adjustable pressure relief valve

- for different levels of engine tune and application

- Sump pan and baffle - our cast dry

sump pan, fitted with an efficient windage plate, can be adapted for any application.

... and of course, hoses, mounting brackets, etc

B r o d i e B r i t t a i n R a c i n g ( B B R - G T i )

(all taken from the BBR website)

Phase

One "Super 140"

(£995 ex. VAT and sold as a kit, £1,295 ex. VAT, fitting included)

BBR developed the Phase One in conjunction with Bell & Colvill, one of the country’s

leading Lotus dealers, for use on the Elise. After supplying these exclusively

to B&C, we are delighted to now offer them for all K-Series applications. The

conversion comprises a specially designed stainless steel exhaust system (all

emission controls remain intact), coupled with a dynamometer-programmed version

of BBR’s unique Interceptor 2000 to handle the revised fuel and ignition requirements

of the engine. Performance is usefully improved throughout the entire range,

making what is already an exciting sports car even more punchy!

Comprising the following

BBR special components:

1. Free-flow stainless steel exhaust system with polished, rolled edge tailpipe/s,

fitted on to the original cat’.

2. Interceptor 2000 fitted to the manufacturers ECU. This device enables the

engine’s running software to be modified, taking advantage of the low back-pressure

exhaust system.

3. High flow air filter.

Power is raised from a lowly 118bhp to approximately 140bhp (+/- 5%) @ 6.800rpm

with a very useful 14lbsft increase of torque. This is by far the best value

and most popular conversion, more than 160 having already been sold world-wide

with over 100 in the UK. The interceptor is the catalyst for Phase One and Two

normally aspirated conversions to the "K" series engines and once fitted, only

software updates are required to suit the more radical modifications. For upgrading

from Phase One to Two, therefore, a substantial discount is available since

Interceptor 2000 is already fitted.

Phase

Two "Super 160"

(£1,800 ex. VAT and sold as a kit, £2,395 ex. VAT, fitting included)

The BBR Phase Two is for those drivers who want more out of their MGF than a

Phase One can offer but who don't (yet!) want the raw power of a Turbocharger.

The Phase Two comprises all that in the Phase One and also a pair of specially

designed camshafts, timed in such a way as to maintain a smooth idle and the

vehicle's low emission output. One distinct advantage of this conversion is

that the upgrade from Phase One to Super Phase One can be carried out at very

little expense and on a while-you-wait basis.

Comprising the following

BBR special components:

1. Free-flow stainless steel exhaust system with polished, twin rolled edge

tailpipes, fitted on to the original cat’.

2. Low-overlap, fast road camshafts.

3. Vernier timing

wheels for optimum timing and performance.

4. Interceptor 2000 fitted to the manufacturers ECU. This device enables the

engine’s running software to be modified, taking advantage of the low back-pressure

exhaust system and revised valve timing.

5. High-flow air filter.

The characteristics of the cam profiles, together with the revised ECU software,

enable vehicles to comply with the latest emission regulations for petrol vehicles

– the vehicle remains "MOT friendly" and idle is unaffected. Power is raised

from a lowly 118bhp to approximately 158bhp (+/- 5%) @ 6.800rpm with

a very useful additional extra 20lbsft of torque.

Phase

Three "Super 185"

(£9,000 ex. VAT, fitting included)

The BBR Phase Three is as far as you would sensibly want to go with a normally

aspirated engine. Anything beyond this would be quite unpleasant for road use.

This conversion is fitted with a gas-flowed, big valve cylinder head, special

fast road/rally camshafts, free-flow stainless steel exhaust system, free-flow

air filter element and the Interceptor 2000. It is very definitely not while-you-wait.

Comprising the following

BBR special components:

1. Forged steel crankshaft.

2. Forged steel connecting rods.

3. Forged aluminium alloy pistons.

4. Free-flow stainless steel exhaust system with polished, twin rolled edge

tailpipes, equipped with a sports cat’ specially developed by Johnson Matthey

for BBR Ltd.

5. Low-overlap, fast road camshafts.

6. Vernier timing wheels for optimum timing and performance.

7. Higher rate valve springs.

8. Gas-flowed cylinder head with oversize valve seats, inlet and exhaust valves.

9. Cast alloy inlet manifold, plenum chamber and throttle elbow.

10. Larger throttle butterfly assembly.

11. Induction/filter system.

12. New fully mapped engine management system.

The new management system incorporates closed loop Lambda operation, the only

way to maintain compliance with EC emission regulations for gasoline powered

passenger vehicles Oct.1st ’97. The software has been carefully mapped on our

Superflow 7100 dynamometer for optimum performance whilst maintaining excellent

fuel consumption characteristics. Power is raised by this conversion from a

lowly 118bhp to approximately 185bhp (+/- 5%) @ 7,500rpm with a useful

increase in torque.

Low Pressure

Turbo "LPT160"

(£4,000 ex. VAT and sold as a kit, £5,000 ex. VAT, fitting included)"

As would be expected from our repuation, we are finalising a range of turbocharged

variations for the MGF. The BBR LPT160 conversion is the first stage, requiring

the minimum amount of internal engine work. This conversion greatly enhances

acceleration due to the significant increase in torque that is not generally

achievable with normally aspirated conversions. The LPT160 is an introduction

to the exciting world of turbocharging.

Comprising the following

BBR special components:

1. High temperature cast iron-alloy exhaust manifold.

2. Hybrid Garrett

T25 turbocharger

3. Revised inlet air box/filter system

4. Free-flow stainless steel exhaust system with polished, twin rolled edge

tailpipes, fitted on to the original cat’.

5. New electronic engine management system.

Power is raised from a lowly 118bhp to approximately 168bhp (+/- 5%) @ 5,000rpm

and torque has been raised from 122lbs ft @ 3,000rpm to 175lbs ft @ 3,250rpm.

Medium

Pressure Turbo "MPT220"

(£10.000 ex. VAT, fitting included)

The next stage up the ladder for turbo enthusiasts is theBBR MPT220. Requiring

a fair amount of internal engine work, very respectable power is achieved -

enough to blow off all but the very pricey Super Cars.

Comprising the following

BBR special components:

1. High temperature cast iron-alloy exhaust manifold.

2. Garrett T25 turbocharger

3. Forged aluminium alloy pistons.

4. Forged steel high performance connecting rods (changed pin centres)

5. Cylinder liner kit.

6. Cast inlet manifold and plenum chamber system.

7. Intercooler system.

8. Revised inlet air box/filter system

9. Gas-flowed cylinder head.

10. Special cylinder head gasket.

11. Free-flow stainless steel exhaust system with polished, twin rolled edge

tailpipes, fitted on to a metallic substrate sports cat’.

12. New electronic engine management system.

Power is raised from a lowly 118bhp to approximately 220bhp (+/- 5%) @ 5,500rpm

and torque has been raised from 122lbs ft @ 3,000rpm to 190lbs ft @ 3,250rpm.

MGF 300

Turbo

The BBR MGF 300 Turbo conversion is aimed at the driver who wants the ultimate

performance from this great little car. The 300bhp engine at the heart of this

conversion was developed and built originally for the Maclaren chief designer,

Adrian Newey. This astonishing power output from the K-Series engine gave his

Lotus Elise performance comparable to the world's fastest super cars and the

same power to weight ratio as the Maclaren F1 road car! The project took 14

months to complete and will shortly be undergoing it's first magazine tests.

Component parts are now available and all of these are either designed in-house

by our own engineers or produced to our specification. Just imagine it, instead

of an F40 Ferrari you can purchase a BBR modified MGF with similar performance

and still have enough loose change left to buy a substantial house and garage

to keep it in!

Engine statistics in

a nutshell

BBR.-GTi modified "K" Series Rover 1800cc 4 cylinder 16 valve

- Bore = 78 mm

- Stroke = 89 mm

- SV/cyl = 425.27 cc

- Total SV = 1,701.09 cc

- CR = 8.5:1

Turbocharged

Max power output = 305 bhp at 6,800 rpm

Max torque = 285 lbs ft at 4,250 rpm

Torque spread min 235lbs ft at 3,500rpm to 6,800rpm

Max engine speed = 7,200rpm

Max boost = 1.3 bar (2.3 bar abs.)

Schedule of engine improvements

and chassis installation modifications

*

Part One, BBR new engine parts and alterations

- Forged, nitrided

steel counterbalanced crankshaft.

- Stronger, heavy-duty cylinder liners.

- Forged aluminium alloy pistons with changed compression height, larger diameter

gudgeon pins and lightweight rings.

- Cylinder block machined for new liners.

- Ladder frame doweled to cylinder block at all main bearing shuts.

- New forged HT steel connecting rods - larger gudgeon pin diameter, new length

to suit pistons.

- Steel crankcase strengthening base-plate machined to accommodate bigger diameter

crankcase studs and drilled with special oil galleries to attach piston oil

spray plumbing.

- Specially manufactured larger crankcase-to-cylinder head HT steel studs.

- Specially manufactured HT steel cylinder head and crankcase nuts.

- Oil spray piston cooling system plumbed to steel base plate and attached to

the cylinder block.

- Cylinder head machined and fitted with larger inlet and exhaust seats.

- Larger tuftrided nickel-steel inlet and exhaust valves.

- Cylinder head gas-flowed.

- Cylinder head machined for stronger gasket arrangement and to fit new exhaust

manifold.

- Stronger cylinder head gasket.

- New inlet manifold, plenum chamber and throttle elbow - designed to maximise

mass airflow with pulse tuned induction length and calculated optimum plenum-chamber

volume. Design uses a larger butterfly assembly with attached throttle angle

sensor. Castings are black anodized aluminium alloy but magnesium castings are

available at extra cost.

- Larger fuel injectors.

- Fuel rail assembly fitted with manifold pressure adjustable fuel pressure

relief valve.

- Fabricated stainless steel exhaust manifold plumbed underneath the engine

to attach to turbocharger on inlet side.

- BBR built and balanced hybrid Garrett T3 turbocharger fitted with BBR 360¡

heavy duty thrust bearing.

- Specially manufactured heavy-duty single plate clutch, organic linings. (no

space in bell housing for twin plates)

- Dyno tested engine. Software written for both fuel and ignition to suit all

situations; e.g.

Warm-up cycle -

warm-up maps

Slow running - slow

running maps

All other throttle

and load positions - main maps

Boost control

Closed Lambda loop

Taking into consideration:

Intake air temperature

Coolant temperature

Intake air (manifold

absolute) pressure

Throttle angle

Limit parameters

*

Part two, in chassis

- Strengthened gearbox

- new closer ratio gears; long first gear (70mph; 112kph)

- BBR LSD – new limited slip differential.

- BBR /Johnson Matthey metallic substrate sports cat’.

- Stainless steel exhaust system, straight through silencer.

- Water to air charge cooler to control induction temperatures. Accommodated

to the rear of the car but plumbed to a water radiator mounted in front of the

main coolant radiator, coolant being circulated by an electric pump, activated

by inlet air temperature/boost level.

- Special in-car plumbing for turbo pipework (including oil feed and drain).

- New engine management control computer and loom, connected to original sensors,

except throttle angle sensor, attached to the new throttle body.

- Fuel system incorporates new pumps, swirl pot and plumbing.

- Engine breather system.

- Modified engine-cooling system incorporating swirl pot and expansion tank.

- Remote oil cooler and oil filter unit

NB: Dry sump kit, optional – see below.

K300T Parts List at a

glance

1 off Forged billet

steel crankshaft

4 off Forged steel connecting rods

4 off Heavy duty cylinder liner

4 off Forged lightweight aluminium alloy heavy-duty performance pistons

4 off Lightweight, high performance, piston ring pack

8 off Oversize inlet valves

8 off Oversize exhaust valves

16 off Oversize valve seats

1 off Cast BBR high performance turbo inlet camshaft

1 off Ditto exhaust camshaft

16 off High performance valve springs

1 off Steel cylinder block strengthening base plate

10 off Crankcase/cylinder head fixing studs

10 off Cylinder head nuts

1 off Heavy duty clutch assembly, organic plate

1 off Cast aluminium alloy inlet manifold

1 off Cast aluminium alloy plenum chamber

1 off Cast aluminium alloy throttle elbow

1 off Throttle assembly

4 off Solenoid higher flow fuel injectors

1 off Fuel rail

1 off Fuel pressure relief valve

1 off Stainless steel exhaust manifold

1 off Stainless steel downpipe (to turbo)

1 off Turbocharger Garrett/BBR T3 hybrid

1 off Stainless steel exhaust pipe, turbo to catalyst

1 off High performance catalyst

1 off Catalyst to silencer link pipe (s.st)

1 off Stainless steel silencer

1 off Polished stainless steel tailpipe assembly

1 off Turbocharger compressor to intercooler pipework

1 off Intercooler – water to air type

1 off Intercooler water cooling radiator

1 off Small bore water pump – intercooler circulation

1 off Intercooler to throttle assembly pipework and intercooler water-cooling

plumbing

1 off Airbox

1 off Highflow air filter

1 off Airbox to turbocharger inlet pipework

1 off Engine management computer

1 off Engine management wiring loom and connector

1 off MAP manifold sensor

1 off Water temperature sensor

1 off Lambda sensor

1 off Throttle angle sensor

1 off Air temperature sensor

1 off Engine speed sensor

1 off Camshaft/engine position sensor

1 off Catalytic converter – stainless steel substrate, heavy loaded Platinum/Rhodium

coating

Optional – recommended

for track use

BBR.-GTi dry sump

kit, comprising:

- Dry sump (modified

from original and including twin scavenge pick-ups and strainers)

- Dry sump pump – twin scavenge

- Dry sump pulleys, brackets and belt

- Dry sump oil tank

- Dry sump pipework

M G X - P o w e r : K 2 0 0 0 E n g i n e

More info on the following page.

2.5 KV6

engine swap

The story starts when Chris Flanagan could manage to put his hands on a brand

new 2.5 liter KV6 engine. At that time, he is still active as an MG Rover technician.

Off course this engine swap isn't as easy as adding one to one. Chris started

with the removal of the K4, installed the V6 on the subframe (the sump needs

some modifications) and changed the engine mounts. After that he continued by

dropping the body and cutting away lumps where the body touched or fouled the

engine. No need to say that creating new panels, welding and some reinforcing

was required. Even the fuel tank needed to be modified. The new tank has a third

less of capacity. Very remarkable is that the precious bootspace hasn't been

touched at all. Instead he has chosen to cut away the front engine bay bulkhead

to clear the front bank of cylinders. To access the spark plugs of the rear

bank of cylinders, he has cut an access panel in the rear bulkhead. To improve

cooling an new radiator and remote oil cooler got installed. Besides an upradted

suspension and braking, modifications to the exhaust were made. He even managed

to install the ZT engine management electronics instead of the ZS box. This

results in a claimed 190bhp instead of the ZS' 180.

Allthough it allready looks very impressive, it is still a prototype.

Contact details:

Chris Flanagan

Spen Vale Garage

Cleckheaton

Tel.: 01274 - 872972

Fax.: 07709 - 248220